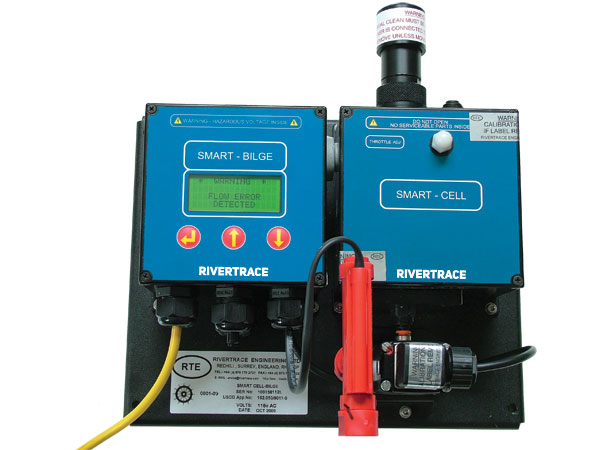

RIVERTRACE - SMART BILGE - 15 PPM OIL CONTENT MONITOR

By utilising the “Smart Cell” Detector Array Technology, developed by Rivertrace, the OCM analyses all three oil types (HFO, Diesel and Emulsions) simultaneously without the need for re-calibration.

A manual cell cleaning device is included as standard to easily enable routine maintenance. Optical cell fouling is recognised as a leading cause of monitor malfunction or incorrect reading. By simple operation of the manual cleaning device, the “Smart Cell” remains in optimum operating condition.

Replacement calibrated measuring cells can be purchased for easy change over on board the vessel and calibration check kits enable the crew to demonstrate the monitor is within factory calibration to PSC Surveyors.

The Smart Cell Bilge Alarm is readily available as a 5ppm version if required. It can also be tailor made for Hazardous Environments (Zone 1 & 2) as an Exd system with Auto Clean, all enclosed in an explosion proof cabinet.

APPLICATIONS

- MEPC 107(49) Bilge Water Discharge

- Rig Slop Tank Discharge

- Air Cooler Drains Overboard Discharge

- Oily Water Separator Discharge

OPTIONS

All options can be ordered from new or retrofitted to existing Rivertrace Smart Bilge monitors.

FLOWSWITCH

The flowswitch option has been designed to ensure that bilge water is flowing through the measuring cell when in monitoring mode. An error is shown on the display if there is no flow.

The flowswitch monitors the flow of water through the cell. This ensures that the flow cannot be shut off accidentally or maliciously. In case of no flow, the Smart Bilge will close the overboard discharge valve.

AUTOCLEAN

The autoclean option has been designed to ensure that the measuring cell glasstube is kept free from fouling. Cell fouling is recognised as a leading cause of monitor malfunction. Fitting the Autoclean removes the need for the ship’s crew to remember to clean the cell manually.

SPECIFICATION

| MEASUREMENT | |

|---|---|

| Oil types: | HFO, Diesel and Mixture C (IMO defined) |

| Clean water calibration: | +/- 2ppm of factory set values |

| Oil range: | 0 – 40 ppm |

| Accuracy oil + solids: | +/- 5ppm up to 30 ppm |

| Solids discrimination: | 100ppm Iron Oxide in 10 ppm Diesel |

| Response time: | < 5 sec (oil reading) |

| ALARMS | |

| Oil alarm 1 setpoint: | 1 – 15 ppm user adjustable |

| Oil alarm 2 setpoint: | 1 – 15 ppm user adjustable |

| Oil alarm 1 delay: | 0 – 5 seconds user adjustable |

| Oil alarm 2 delay: | 0 – 600 seconds user adjustable |

| INPUT / OUTPUT | |

| Analogue output: | Active 4-20mA / 0 – 20mA |

| Switch inputs: | 2 x switch inputs for separator and backflush status |

| DATA STORAGE AND RETRIEVAL | |

| Calibrate on data storage: | Stored in cell |

| IMO required data: | Stored in Control enclosure |

| IMO required data retrieval: | Via LCD display, RS 232 comms link or USB |

| SYSTEM AND SUPPLY | |

| Supply voltage: | 115 or 230V AC, 50 – 60Hz (24V AC & 12V DC available) |

| Supply voltage Consumption: | < 50 VA incl. solenoid valve |

| Supply voltage tolerance: | +/- 15% |

| Projected life: | > 50,000 hrs |

| Protection class: | IP 65 |

| Approvals: | MEPC 107(49) – DNV-GL, USCG, CCS, Class NK, Russian Register, Transport Canada. |

| Weight: | 3.2 Kg / 7.05lb |

Specifications and system descriptions accurate at time of printing. These are subject to change.

The monitor’s calibration can be checked using our calibration check kit. This is an approved method of demonstrating that the unit is still working correctly to Port State Control and Class.

Guidelines : *MEPC 107(49)*

"4.2.11 The validity of calibration certificates should be checked at IOPP annual/intermediate/renewal surveys. The accuracy of 15 ppm bilge alarms is to be checked by calibration and testing of the equipment conducted by a manufacturer or persons authorized by the manufacturer and should be done at intervals not exceeding five years or within the term specified in the manufacturer's instructions, whichever is shorter.

Alternatively the unit may be replaced by a calibrated 15 ppm bilge alarm.

The calibration certificate for the 15 ppm bilge alarm, certifying the date of the last calibration check, should be retained on board for inspection purposes.

The accuracy checks can only be done by the manufacturer or persons authorized by the manufacturer." *MARPOL Annex I - Chap.2-Reg.10

1. An International Oil Pollution Prevention Certificate shall be issued for a period specified by the Administration, which shall not exceed five years.