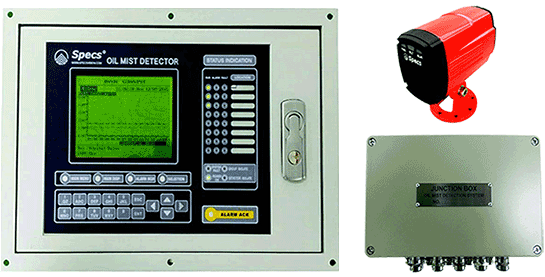

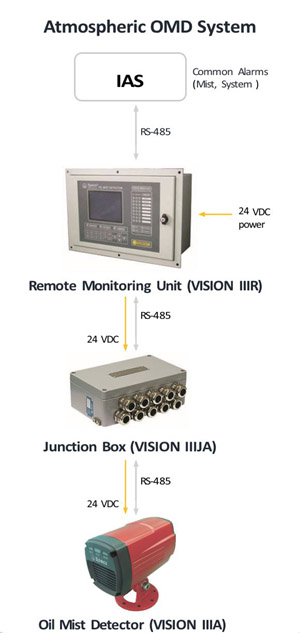

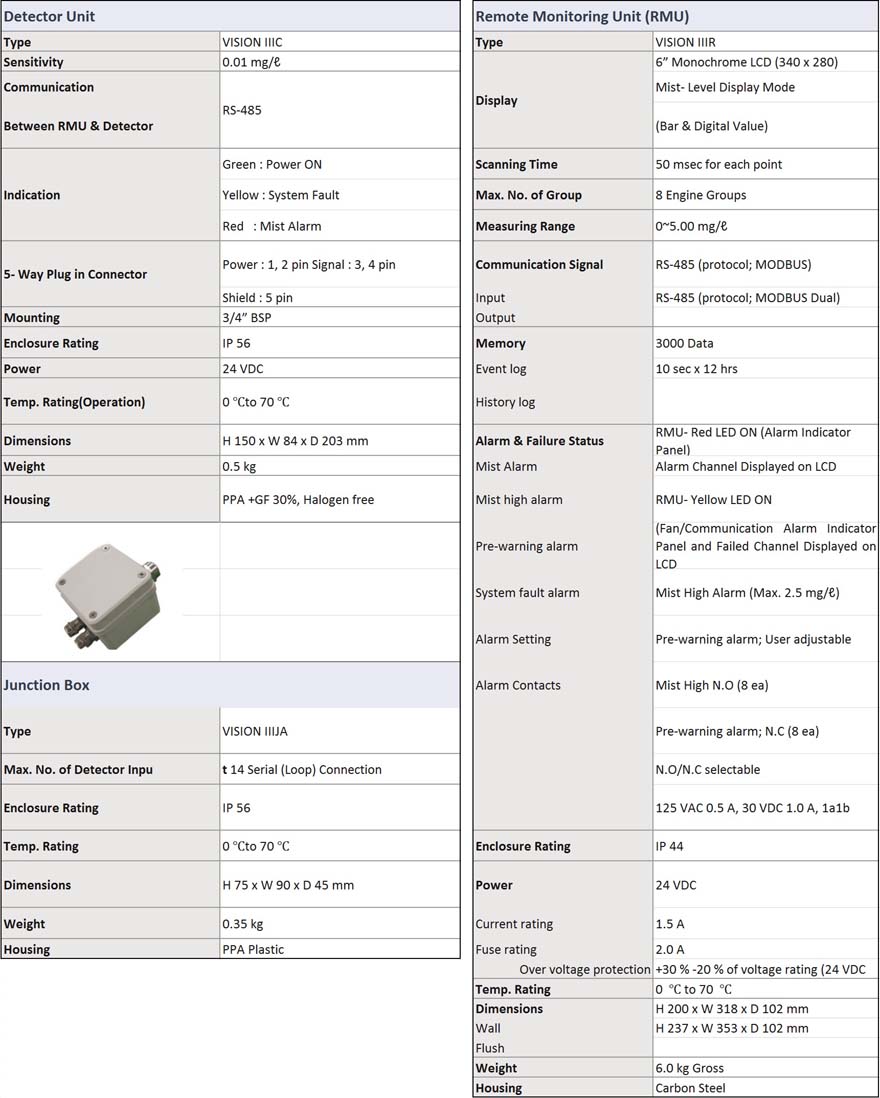

Specs Oil Mist Detector

SPECS has achieved world-wide recognition for the quality and function of its engine room oil mist detector (AOMD) and crankcase oil mist detector (COMD).

The company also supplies various monitoring systems for ship safety and maintenance. It has developed a bearing wear monitoring system (BWMS) to predict bearing wear in 2-stroke engines before the condition becomes critical. The system provides early warning alarm and a slow down signal if unexpected problems arise with any of the crank-train bearings, including crosshead, crank and main bearings.

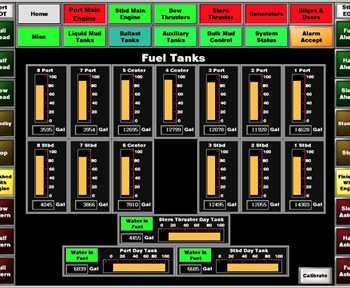

SPECS also offers a ship energy efficiency monitoring system (SEEMS) that collects real-time signals related to the efficiency and performance of ship operation, analyzes the information and stores the calculated data. It calculates and displays EEOI & CO2 emission values based on IMO guidelines, presents trend graphs of the data over variable time periods, and presents daily, voyage and sea trial reports.

With more than 150 different data points, the system enables engineers to maintain an optimum ship maintenance schedule.

Specs Corporation Team